Not long ago, fingerprint scanners and swipe cards were seen as cutting-edge in factory attendance tracking.

They were a big step forward from manual registers, eliminating some errors and making it harder to fake attendance.

But in 2025, manufacturing companies are realizing these old biometric methods aren’t keeping up with the demands of:

- Faster shift changes

- Tighter security

- Strict labor compliance

- Hybrid workforce management

The next evolution?

AI-powered face recognition attendance systems — combining speed, security, and analytics into one seamless process.

When integrated with AI Attendance Management Systems, AI Face Recognition Machines, and Factory Workforce Tracking Solutions, they’re transforming how manufacturing plants manage time, security, and compliance.

1. The Limitations of Old Biometrics in Manufacturing

While fingerprint scanners, iris scanners, and swipe cards worked well initially, they now create more problems than they solve.

a. Hygiene Issues

Factories — especially food, pharmaceuticals, and healthcare-related manufacturing — can’t risk workers touching the same surface hundreds of times a day.

High-touch devices are a hygiene hazard.

b. Throughput Problems

Fingerprint and card systems often cause bottlenecks during shift changes, slowing down hundreds of workers trying to clock in at once.

c. Environmental Wear and Tear

Dust, oil, grease, and gloves interfere with fingerprint scanners.

Magnetic swipe cards wear out quickly and need constant replacement.

d. Fraud & Security Risks

- Swipe cards can be shared.

- Fingerprints can be spoofed with replicas.

- PIN codes can be guessed or passed along.

2. Why AI Face Recognition Attendance is More Reliable

AI-powered face recognition isn’t just a newer version of biometrics — it’s a complete paradigm shift.

a. True Contactless Check-In

Workers simply walk past a device — no touching required.

b. Works Through PPE

Advanced AI can identify workers even if they are wearing helmets, safety goggles, or masks — critical in manufacturing environments.

c. Speed & Efficiency

Under 1-second verification keeps entry lines moving, even in plants with thousands of employees.

d. Liveness Detection

The AI confirms a real, live person is present — blocking photo, video, or mask spoofing.

e. 24/7 Accuracy in Any Condition

Whether indoors under dim light or at outdoor gates in bright sun, AI maintains high accuracy rates.

3. Benefits of AI Face Recognition in Manufacturing Attendance

1. Eliminates Buddy Punching

Fraudulent check-ins — where one worker clocks in for another — are impossible.

2. Improves Punctuality

Real-time alerts notify managers of late arrivals, reducing shift delays.

3. Enhances Security

Role-based access ensures only trained and authorized workers can enter certain areas.

4. Reduces Payroll Errors

Accurate attendance data integrates directly with payroll, preventing overpayments.

5. Meets Compliance Requirements

Automatic recordkeeping helps with ISO, OSHA, and labor law audits.

4. Why Face Recognition is Better for Factory Environments

Factories are high-traffic, high-variance environments — dusty, noisy, and often requiring safety gear.

Face recognition thrives where other biometric methods fail:

| Feature | Fingerprint Biometrics | AI Face Recognition |

| Contactless | ❌ No | ✅ Yes |

| PPE Compatibility | ❌ Low | ✅ High |

| Speed | ❌ Medium | ✅ Fast (<1s) |

| Fraud Prevention | ❌ Weak | ✅ Strong (Liveness) |

| Environmental Durability | ❌ Poor | ✅ Excellent |

5. Integration with Factory Systems

AI face recognition systems become far more powerful when linked with:

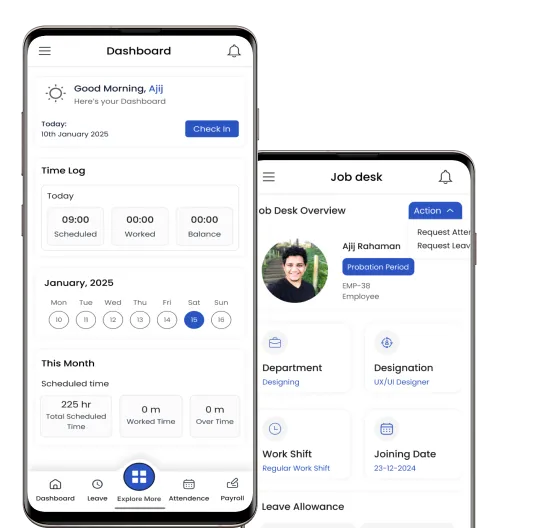

- AI Attendance Management Systems → Centralized dashboards for all shifts and locations.

- AI Employee Monitoring Tools → Match attendance with actual productivity.

- Factory Payroll Systems → Automate overtime and bonus calculations.

6. Real-World Case Study

A mid-sized automotive parts factory replaced fingerprint scanners with AI face recognition attendance devices at all entry points.

Results in 90 days:

- Check-in times cut from 4 minutes to under 1 minute for 100+ workers

- 100% elimination of buddy punching

- Reduced payroll discrepancies by 18%

- Passed labor compliance audits with zero attendance disputes

7. The Future of Factory Attendance

AI attendance systems are evolving toward:

- IoT Integration → Machines start up only when the right worker checks in.

- PPE Verification → Entry denied if safety gear is missing.

- Predictive Scheduling → AI assigns shifts based on attendance and performance trends.

Conclusion: Time to Move Beyond Old Biometrics

Fingerprint scanners, swipe cards, and PIN codes had their time — but in modern manufacturing, they can’t deliver the speed, accuracy, and security needed.

AI face recognition attendance systems:

- Remove contact-based risks

- Stop fraud before it happens

- Integrate with payroll, compliance, and productivity tracking

- Keep factories running smoothly, securely, and on time

For manufacturing companies, upgrading from old biometrics to AI-powered face recognition isn’t just about attendance — it’s about future-proofing the entire workforce management process.