In manufacturing, every minute on the clock matters — especially in industries where shifts run with precise timing and strict compliance rules.

Gone are the days of:

- Punch cards getting misplaced

- Swipe cards being shared

- Manual registers prone to errors

Today, manufacturing companies are adopting AI face recognition attendance systems that:

- Identify workers in less than a second

- Prevent buddy punching

- Provide real-time workforce analytics

And the future of check-ins is looking even smarter, with AI-driven innovations that connect attendance, productivity, and safety.

1. The Rise of Contactless Workforce Check-ins

Why it matters for manufacturing:

Factories often have high foot traffic during shift changes, making hygiene and speed critical.

- Touch-free entry reduces contamination risks in food processing and healthcare manufacturing.

- AI can identify workers even when wearing helmets, safety goggles, or masks.

Linked with AI attendance management systems, these check-ins become part of a seamless shift management process.

2. Multi-Entry Synchronization for Large Facilities

Manufacturing plants often have multiple entry gates.

With AI-powered check-ins:

- Data from all gates syncs instantly in the cloud.

- Plant managers can see live workforce numbers on the floor.

- HR teams can monitor attendance trends across multiple factories.

When integrated with AI employee monitoring tools, this also helps correlate attendance with machine utilization.

3. AI-Powered Fraud Prevention

Buddy punching costs manufacturing companies millions annually in lost productivity.

Future AI systems are moving beyond basic face matching to:

- Use liveness detection to prevent spoofing via photos or videos.

- Cross-reference shift schedules to flag unusual patterns.

- Trigger alerts if an employee tries to check in at an unauthorized gate.

4. Predictive Shift Scheduling

Next-gen AI attendance systems won’t just log arrivals — they’ll:

- Predict worker availability based on past attendance patterns.

- Suggest optimal shift allocations to reduce overtime costs.

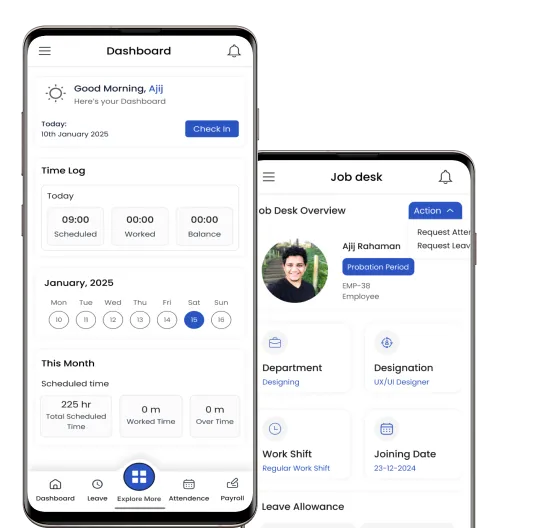

- Notify workers in advance about schedule changes via mobile apps.

This is a huge advantage for multi-shift factories where scheduling errors can halt production.

5. Integration with Safety Systems

Manufacturing environments are high-risk, so safety compliance is as important as attendance.

Future AI check-in systems may:

- Verify PPE compliance before allowing entry.

- Block access if a worker hasn’t completed required safety training.

- Flag workers who are over their safe working hours.

6. Cloud-Based Attendance & Analytics

With cloud integration, manufacturers can:

- View real-time headcounts from anywhere.

- Generate compliance reports instantly for audits.

- Store attendance history securely for years.

This also enables centralized management for companies with multiple factories across regions.

7. AI & IoT Convergence

The next phase is AI + IoT integration:

- Check-ins trigger machine power-ups.

- Break logouts pause machinery for safety.

- Sensors detect if an employee is in the correct work zone during their shift.

8. The Role of Emotion AI in the Future

While still emerging, Emotion AI could help detect:

- Fatigue levels before starting a shift

- Stress indicators in high-pressure production environments

This could lead to proactive scheduling changes to reduce accidents.

Conclusion: Smarter Check-ins Mean Smarter Factories

The future of workforce check-ins in manufacturing goes far beyond recording time.

With AI face recognition linked to:

- AI attendance management systems

- AI productivity trackers

- AI monitoring tools

…manufacturers can achieve:

- Faster, safer check-ins

- Zero attendance fraud

- Better shift scheduling

- Higher compliance and productivity

Factories that invest in next-generation AI attendance technology now will set the standard for efficiency, security, and worker safety in the years to come.