Running a factory in India is not easy. There is always pressure to manage people, shifts, deadlines, and daily operations. In the middle of all this, tracking attendance becomes a big challenge. Many factories still use old methods, which create mistakes, confusion, and extra work. This is why many companies now seek smart Attendance Software to address these issues and keep things running smoothly.

Here are some of the most common attendance problems Indian factories deal with every day:-

1. Too Much Manual Work

2. Shift Changes and Rotation Confusion

3. Buddy Punching and Fake Attendance

4. No Integration With Payroll

5. Handling Overtime the Right Way

6. Tracking Contract Workers

7. Lack of Real-Time Data

Too Much Manual Work:

Many factories still use paper registers or simple spreadsheets to mark attendance. These methods feel easy, but they create a lot of work later. HR teams spend hours counting late marks, half-days, overtime, and working hours. One small mistake in a register can mess up the entire month’s salary. Manual work also slows down decisions and increases stress during payroll time. A digital tool speeds up and improves the accuracy of this process.

Shift Changes and Rotation Confusion:

Factories run on multiple shifts, and these shifts change often. Workers rotate between morning, evening, and night shifts as needed. When shifts change suddenly, attendance records get mixed up. HR teams struggle to track who worked which shift and for how long. This is where strong Attendance Management Software helps by adjusting shifts automatically and keeping every record clean and accurate.

Buddy Punching and Fake Attendance:

Buddy punching is one of the biggest issues in factories. When a worker punches attendance for a friend, it creates false records. This leads to unfair payouts, financial losses, and poor discipline. Traditional systems cannot catch this. Modern biometric or face-recognition devices help solve this problem. They ensure that the right person marks the attendance every time. This brings fairness and trust inside the factory.

No Integration With Payroll:

Attendance and payroll must work together. But in many factories, they operate separately. HR teams collect attendance data from machines, then re-enter it in payroll software. This double work increases mistakes and delays. A good Attendance Management System connects attendance, leaves, overtime, and payroll in one place. This saves hours of work and helps the HR team finish salary processing without stress.

Handling Overtime the Right Way:

Overtime is very common in factories, but most companies struggle to track it correctly. Workers stay late, supervisors approve it later, and records don’t always match. This leads to confusion during salary calculation. A proper attendance system automatically records overtime and produces clear reports. Workers also feel satisfied because they know their extra hours get counted correctly.

Tracking Contract Workers:

Factories hire many contract workers, and their attendance is often harder to track. They join for short periods, and their shift timings keep changing. Many contractors also send attendance lists late, which delays salary. A digital attendance system helps factories track contract workers more accurately and separately. This keeps payments clean and avoids disagreements with contractors.

Lack of Real-Time Data:

Factory owners need real-time attendance information to plan production and manpower. But manual systems show outdated data. Without real-time numbers, managers cannot make quick decisions. Digital attendance tools give instant data—who is present, who is absent, who is late, and how many workers are available on each line. This helps the factory run smoothly even on busy days.

Conclusion

Attendance becomes simpler and more accurate when factories use smart digital tools. With clear shift tracking, real-time data, and reliable Attendance Management Software, factories reduce errors, save time, and stay organised. The right system supports smoother operations and a more efficient workforce.

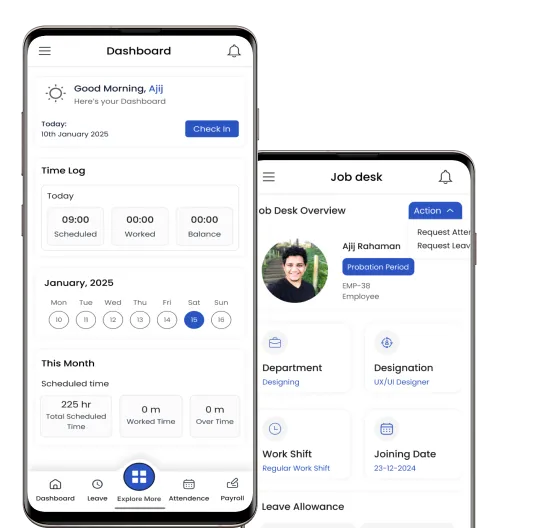

Searching for a simple way to fix daily attendance issues? PagarAI’s Attendance Software helps factories accurately track workers, manage shifts, prevent buddy punching, and sync attendance with payroll in one place. Want to make attendance stress-free and reliable? Book a quick demo today.