In factories and manufacturing plants, time is money — literally.

Every minute lost due to late arrivals, buddy punching, or attendance errors can delay production, increase overtime costs, and affect delivery deadlines.

Traditional attendance methods — manual logs, swipe cards, or basic biometrics — often can’t keep up with:

- Multiple shift schedules

- Large workforces across different entry points

- Compliance requirements for labor laws and safety

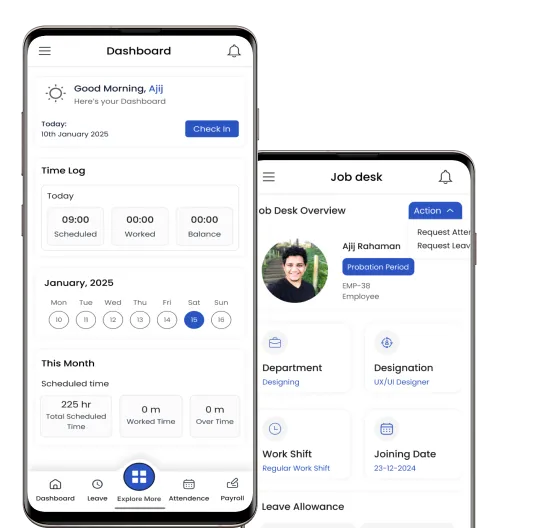

That’s why many manufacturing companies are switching to AI attendance tracking systems that combine AI face recognition, real-time analytics, and shift management automation.

When paired with AI attendance management software and AI employee monitoring tools, these systems don’t just record time — they optimize workforce efficiency.

1. Challenges of Attendance in Manufacturing

Factories have unique attendance challenges:

- Multiple Shifts → Day, night, rotating shifts require precise logging.

- Large Entry Points → Dozens or hundreds of workers arriving at once.

- Buddy Punching → Co-workers clocking in for absent colleagues.

- Compliance Tracking → Overtime and break adherence must meet legal standards.

- Safety & Security → Only authorized workers should access production areas.

2. How AI Attendance Tracking Solves These Problems

a. Biometric Accuracy

Face recognition verifies each worker’s identity instantly, preventing buddy punching.

b. Fast Check-ins

Recognition in under 1 second keeps entry gates flowing smoothly during shift changes.

c. Real-Time Shift Monitoring

Managers can see exactly who’s on the floor, who’s late, and who’s absent.

d. Compliance Automation

AI ensures shift lengths, breaks, and overtime are within labor law requirements.

e. Integration with AI Employee Monitoring

Links attendance with actual machine usage or workstation activity.

3. Key Features for Factory Attendance Systems

When choosing an AI attendance solution for manufacturing, look for:

- Rugged Hardware → Dust, humidity, and vibration resistance.

- Multi-Entry Syncing → Data from different gates updates instantly in the cloud.

- Shift Scheduling Tools → Automatic shift allocation and reminders.

- Offline Capability → Works even if network connectivity drops.

- Integration with Payroll → Instant overtime and bonus calculations.

4. Benefits for Manufacturing Companies

a. Eliminate Time Theft

No shared cards, PINs, or fake check-ins.

b. Reduce Overtime Costs

Track hours precisely to avoid overpayment.

c. Improve Productivity

Late arrivals drop when check-ins are biometric and visible to managers in real time.

d. Centralized Data

For companies with multiple plants, all attendance logs are stored in one system.

5. Real-World Example

A mid-sized automotive parts factory introduced AI face recognition attendance machines at its three entry points.

Results in 90 days:

- 25% drop in late arrivals

- Eliminated all buddy punching

- Saved $18,000 in overtime costs by accurate shift tracking

6. Industry-Specific Use Cases

- Automotive Manufacturing → Monitor rotating assembly line shifts.

- Food Processing Plants → Ensure hygiene with contactless check-ins.

- Textile Factories → Manage seasonal worker influx efficiently.

- Electronics Production → Maintain strict shift and access control.

7. Compliance & Security

AI attendance systems store biometric data in encrypted templates, ensuring:

- GDPR & CCPA compliance

- Role-based access for HR and plant managers

- Audit-ready attendance reports

8. The Future of Factory Attendance

In the next 5 years, expect:

- IoT Integration → Machines log start times when an employee clocks in.

- Predictive Shift Scheduling → AI assigns shifts based on worker availability and performance history.

- Emotion AI → Detect fatigue or stress during check-in for safety monitoring.

Conclusion: AI is the New Standard for Factory Attendance

In manufacturing, accuracy, speed, and security aren’t optional — they’re business-critical.

An AI attendance tracking system:

- Keeps shift changes smooth

- Prevents buddy punching

- Reduces payroll errors

- Integrates with AI attendance management software, AI monitoring tools, and AI productivity trackers

For factories ready to improve efficiency and compliance, AI attendance tracking isn’t just an upgrade — it’s a competitive advantage.