For a single factory, tracking attendance is already challenging.

For manufacturing companies with multiple plants across different locations, the complexity multiplies:

- Different shift timings in each plant

- Thousands of workers entering through multiple gates

- Variations in local labor laws

- Inconsistent attendance tracking methods

Manual systems, swipe cards, or even standalone biometric devices can’t keep up with the demands of real-time, multi-location attendance management.

The solution?

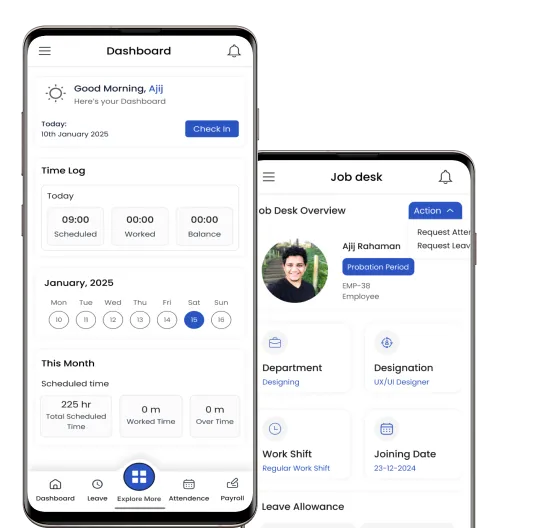

AI attendance management systems that connect all factories into one centralized platform, integrate with AI face recognition devices, and link to AI employee monitoring tools for a complete view of workforce performance.

1. Why Multi-Location Manufacturing Needs Centralized AI Attendance

- Consistency → Same policies, features, and rules across all locations.

- Fraud Prevention → Stop buddy punching in every plant.

- Compliance → Meet regional labor laws without manual reporting.

- Productivity Insights → Link attendance with production output.

2. How AI Attendance Management Works for Multiple Plants

a. Cloud-Based Sync

Data from each plant is uploaded instantly to a central dashboard.

b. Multi-Gate & Multi-Shift Tracking

Handles workers entering from multiple gates and working in rotating shifts.

c. Role-Based Access

- Plant managers see local attendance.

- HR sees company-wide attendance.

- Executives see consolidated performance reports.

d. Integration with AI Productivity Tracker

Matches attendance with shift efficiency and machine utilization.

3. Key Features for Multi-Location Manufacturing

- Real-Time Headcount across all plants

- Geo-Fencing for authorized site check-ins

- Automated Shift Scheduling company-wide

- Overtime Management to avoid excess costs

- Centralized Payroll Integration

4. Benefits for Manufacturing Companies

a. Centralized Oversight

Executives can see exactly how many workers are active in each plant in real time.

b. Standardized Policies

Same attendance and punctuality rules across all locations.

c. Fraud Detection at Scale

If an employee tries to check in at two locations simultaneously, the system flags it.

d. Reduced Administrative Load

No need for each plant to maintain separate attendance databases.

5. Real-World Example

A multinational electronics manufacturer with 7 plants in 3 states switched from manual biometric logs to an AI attendance management system.

In the first year:

- Eliminated buddy punching across all plants

- Reduced payroll processing time by 40%

- Saved $220,000 in overtime cost adjustments

6. Industry-Specific Applications

- Automotive Plants → Track shift compliance across assembly lines.

- Textile Factories → Manage seasonal staffing in multiple regions.

- Food Processing Plants → Monitor hygiene compliance during check-ins.

- Electronics Manufacturing → Track specialized technician availability.

7. Compliance Across Locations

AI systems can be programmed to:

- Apply local overtime laws automatically.

- Generate region-specific reports for audits.

- Maintain encrypted biometric records for all employees.

8. Future Trends for Multi-Location Attendance

- AI-Driven Staffing Optimization → Allocate workers where needed most in real time.

- IoT Integration → Machine access tied to attendance check-ins.

- Predictive Absenteeism Alerts → AI detects patterns before staffing gaps happen.

Conclusion: One Dashboard, All Plants, Real Results

For manufacturing companies with multiple locations, AI attendance management delivers:

- Centralized control

- Consistent policies

- Real-time insights

- Fraud prevention at scale

When combined with AI face recognition attendance machines, AI employee monitoring tools, and AI productivity trackers, it becomes the backbone of an efficient, compliant, and profitable workforce.

Multi-location attendance tracking isn’t just about keeping records — it’s about running smarter factories.