In manufacturing, shift planning is more than just making a schedule.

It’s about ensuring the right number of skilled workers are in the right place at the right time — without wasting labor hours or slowing production.

The problem?

Traditional attendance systems can’t give real-time visibility into workforce availability.

If someone calls in sick or arrives late, managers often find out after the shift starts, leading to:

- Understaffed lines

- Overtime costs

- Production delays

This is where AI-powered face recognition attendance systems change the game.

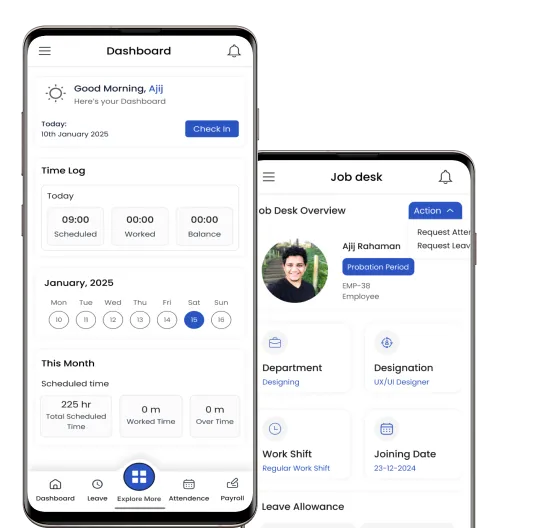

When integrated with AI Attendance Management Systems and AI Productivity Trackers, they enable real-time shift planning and workforce optimization.

1. The Challenges of Traditional Shift Planning in Factories

Manufacturing shift scheduling faces unique problems:

a. Last-Minute Absences

A single no-show can delay production if replacements aren’t arranged quickly.

b. Inaccurate Attendance Data

With old systems, managers don’t know who’s actually on-site until well into the shift.

c. Overtime Overruns

Without precise attendance and shift overlap tracking, overtime hours often go unnoticed until payroll processing.

d. Cross-Site Coordination

In multi-location manufacturing, it’s hard to reallocate staff across plants without live data.

2. How AI Attendance Transforms Shift Planning

AI face recognition attendance systems go beyond recording check-ins — they provide instant workforce intelligence.

a. Real-Time Workforce Visibility

- Managers see who is on-site, in which department, and when they arrived.

- Automatic alerts for late arrivals or absentees.

b. Predictive Shift Adjustments

- AI analyzes attendance patterns to predict staffing gaps before they happen.

- Suggests replacements from available standby or cross-trained workers.

c. Integration with Scheduling Software

- Attendance data syncs with shift scheduling tools.

- Automatic updates when shifts change due to unexpected absences.

3. Benefits of AI Attendance for Workforce Optimization

1. Eliminate Shift Start Delays

Workers are verified in under 1 second, even with PPE.

💡 Learn more: How Face Recognition Cuts Shift Delays in Manufacturing Plants

2. Improve Labor Cost Efficiency

Accurate attendance prevents overstaffing or unnecessary overtime.

3. Better Departmental Allocation

Managers can reassign workers instantly based on live attendance data.

4. Reduce Unplanned Overtime

Automatic alerts when workers exceed scheduled hours.

4. AI Attendance + Productivity Tracking = Smarter Workforce Management

When AI Attendance Systems are combined with AI Productivity Trackers:

- Managers can see not just who is present, but who is performing efficiently.

- Underperforming teams can be flagged for training or reassignment.

- Shifts can be balanced based on actual productivity data, not assumptions.

5. Case Study: Optimizing Shifts in a Multi-Plant Manufacturer

A national packaging manufacturer struggled with shift planning across three factories.

Before:

- Frequent under- or overstaffing

- 12–15% overtime cost over budget

- Delays in production start due to missing staff

After implementing AI attendance:

- Real-time dashboards for all locations

- 40% reduction in unplanned overtime

- Shift delays nearly eliminated

- Reallocation of staff between plants possible in under 10 minutes

6. How AI Attendance Helps in Demand-Driven Manufacturing

In plants where production changes daily based on orders, staffing needs vary constantly.

AI attendance helps by:

- Matching attendance records with production orders

- Automatically alerting when specific skill sets are missing

- Assisting in quick shift reassignments to meet demand spikes

7. Integration with Factory Safety Compliance

Shift planning isn’t just about numbers — it’s about qualified and compliant staff.

With PPE detection built into attendance systems (PPE Compliance Made Easy with AI Face Attendance Systems):

- Workers without required safety gear are flagged or denied entry

- Shifts are always staffed with compliant personnel

8. Preparing for the Future: AI-Driven Autonomous Scheduling

Within the next 5 years, expect to see:

- AI auto-scheduling based on attendance + productivity + demand forecasts

- Dynamic shift swaps where AI assigns backups automatically

- Integration with IoT so production lines only run when fully staffed

Conclusion: Smarter Shifts, Higher Output

Factory success depends on having the right people in the right place at the right time.

AI-powered face recognition attendance systems:

- Give managers real-time workforce visibility

- Enable predictive shift adjustments

- Reduce costs by eliminating inefficiencies

- Integrate with productivity tracking for deeper insights

For manufacturing plants, this is more than attendance tracking — it’s the foundation for optimized workforce management.

If your shift planning is still based on outdated systems and guesswork, it’s time to upgrade to AI Attendance Management Systems and Factory Face Recognition Solutions.