For years, fingerprint attendance systems were the go-to biometric solution for factories and manufacturing plants. They seemed foolproof — unique to each worker, impossible to “share,” and relatively quick to use.

But as factories grow larger, shift patterns get tighter, and hygiene becomes a bigger concern, these systems are showing their limitations.

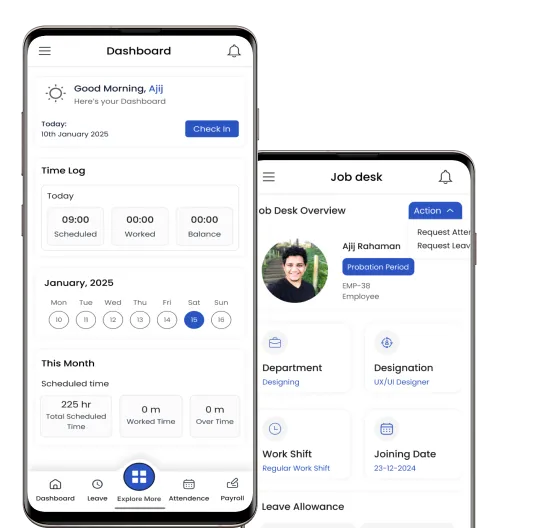

In 2025, manufacturing companies are increasingly replacing fingerprint devices with AI-powered face recognition attendance systems that are:

- Faster

- Contactless

- More accurate in real-world factory conditions

- Better integrated with AI Attendance Management Systems and Factory Workforce Tracking

In this article, we’ll explore the five biggest problems with fingerprint attendance in manufacturing — and how AI face recognition technology solves them.

Problem #1: Hygiene Risks in High-Touch Devices

Why It’s a Problem

Factories — especially those in food processing, pharmaceuticals, and healthcare manufacturing — have strict hygiene protocols. Fingerprint scanners are high-contact devices.

Every shift, hundreds of workers touch the same surface, creating a hotspot for germs.

During COVID-19 and beyond, this became a major health risk. Workers were uncomfortable touching scanners, and some factories saw increased absenteeism linked to these shared surfaces.

How AI Face Recognition Fixes It

- Completely contactless → Workers simply walk past or glance at the device.

- No physical wear and tear from repeated use.

- Hygiene-friendly for cleanroom and food-grade environments.

💡 Tip: In industries where contamination control is critical, AI face recognition is not just a convenience — it’s a compliance necessity.

Problem #2: Slowing Down Shift Changes

Why It’s a Problem

Fingerprint attendance is slower than it looks — workers have to:

- Remove gloves (if wearing them)

- Place their finger just right

- Sometimes try again if the scanner fails to read it

This can take 5–10 seconds per person. In a factory with 500 workers arriving at once, those extra seconds cause bottlenecks at the gates, delaying production start times.

How AI Face Recognition Fixes It

- Under 1-second verification for each worker.

- Works through PPE (helmets, goggles, masks).

- Can process large crowds quickly, reducing entry queues.

When integrated with AI Attendance Management, the system instantly updates headcounts for shift supervisors.

Problem #3: Environmental Interference

Why It’s a Problem

Factories are not office environments — they’re dusty, humid, sometimes oily, and full of moving equipment.

Fingerprint scanners fail more often in these conditions because:

- Dirt or oil on fingers disrupts readings

- Moisture affects scanner sensitivity

- Physical wear damages the sensor surface

How AI Face Recognition Fixes It

- Works in dusty, wet, or outdoor factory gates without reduced accuracy.

- No direct contact means no sensor wear.

- High-definition cameras + AI algorithms ensure recognition even in low-light or harsh sunlight.

In outdoor security gates, this reliability is a major win over old biometrics.

Problem #4: Security & Fraud Loopholes

Why It’s a Problem

While fingerprints are unique, the systems themselves can be gamed:

- Stolen or duplicated fingerprint templates (yes, it’s possible)

- Shared access cards for hybrid systems

- Manual overrides that allow unauthorized entry

And of course — buddy punching — where someone clocks in for an absent co-worker — still happens in mixed biometric setups.

How AI Face Recognition Fixes It

- Liveness detection → Prevents spoofing with photos, videos, or masks.

- Role-based access control → Only authorized staff can enter certain zones.

- Instant alerts for suspicious attempts.

- Eliminates buddy punching entirely.

When combined with AI Employee Monitoring Tools, managers can verify that the person who checked in is also the person operating the machinery.

Problem #5: Limited Integration with Modern Workforce Systems

Why It’s a Problem

Many fingerprint systems are standalone devices. Data is often exported manually and then entered into payroll or HR software — a slow, error-prone process.

In multi-location manufacturing, this means:

- Delayed attendance reporting

- Inconsistent data between plants

- No real-time visibility for managers

How AI Face Recognition Fixes It

- Cloud-based syncing → Attendance logs from all locations update in one central dashboard.

- Instant integration with payroll → Automatic overtime, leave, and bonus calculations.

- Real-time data → Supervisors know exactly who’s on-site at any moment.

Bonus: Financial Benefits of the Upgrade

Switching from fingerprint to AI face recognition attendance can:

- Cut payroll errors → Saving thousands per year

- Reduce overtime fraud → Directly lowering labor costs

- Increase productivity → Fewer delays during shift transitions

A large-scale steel manufacturing plant saved over $250,000 annually after switching to AI attendance by removing fraud and improving shift efficiency.

Real-World Case Study: Fingerprint to Face Recognition in Action

A mid-sized electronics assembly plant faced constant delays at entry points due to fingerprint scanner failures.

After installing AI Face Recognition Attendance Machines:

- Shift check-ins dropped from 5 minutes to under 1 minute

- Eliminated buddy punching completely

- Payroll processing time reduced by 35%

- Compliance audit reports generated instantly from the cloud

Conclusion: Time to Retire Fingerprint Attendance in Factories

Fingerprint systems had their moment — but in modern manufacturing, they fall short on:

- Hygiene

- Speed

- Environmental reliability

- Security

- Integration

AI face recognition attendance systems solve all these issues while offering:

- Instant, contactless verification

- Fraud prevention with liveness detection

- Seamless payroll and HR integration

- Real-time multi-location workforce tracking

Factories that make the switch are not just improving attendance — they’re future-proofing workforce security, compliance, and efficiency.

If you’re still using outdated fingerprint scanners, it’s time to upgrade.

Explore how AI Attendance Management Systems and Factory Face Recognition Solutions can transform your plant operations today.